Our experience of tool and die-making is built into the CAM software, making the creation of dies simple and accurate.

We understand that every machine is different and Impact die-making software will adapt to your customers’ specific requirements, meaning their packaging is perfect every time without the need to purchase new equipment.

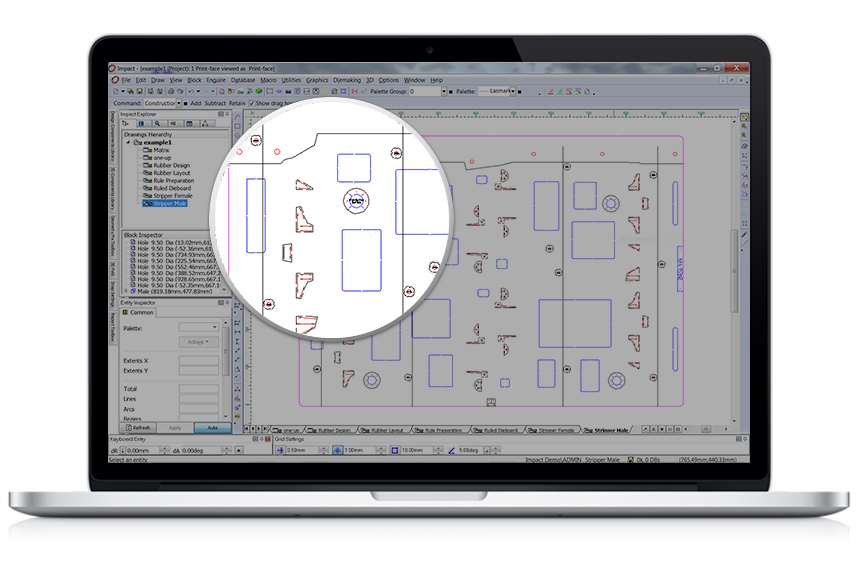

Our die-making CAD and CAM software leads you through a series of logical steps to create the perfect die every time.

Dynamic feedback, in-built preferences and automated process all make your life easier and your customers happier.

You’ll have access to our comprehensive library of best practice industry standard tooling settings. These settings can be easily adapted to yours and your customers’ own defaults and cover all the styles and materials you will encounter.

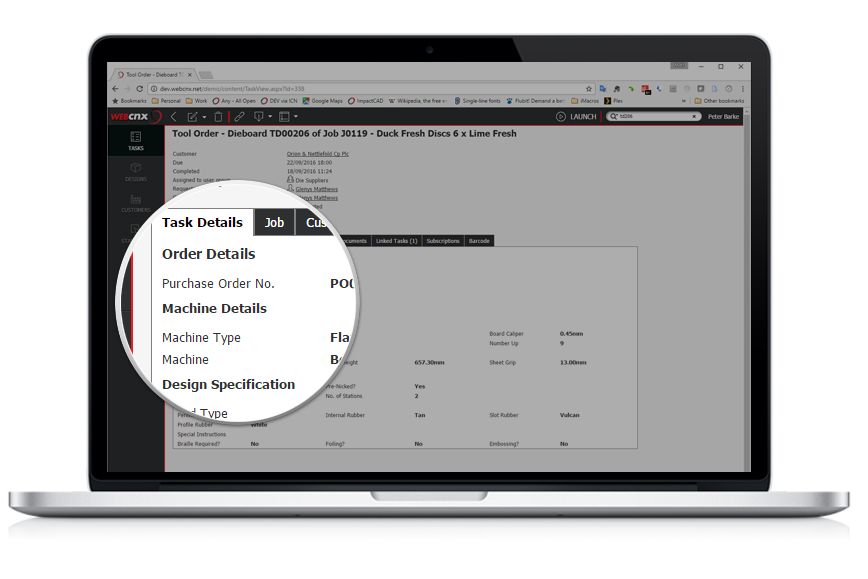

Customer specifications can then be stored and reused automatically, providing maximum productivity and guaranteed quality control.

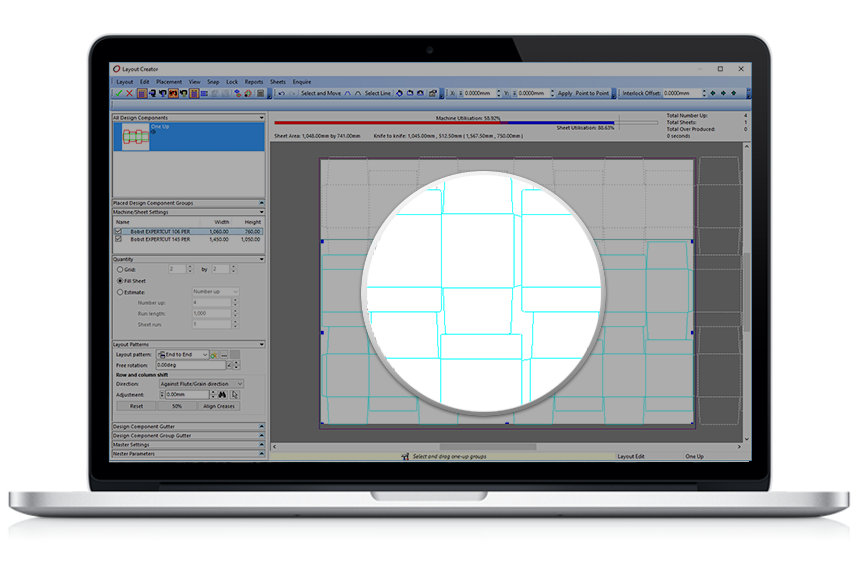

We understand your need for efficiency and our Impact die-making CAM software allows you to calculate one, or multiple, interlocking nesting patterns simultaneously to ensure maximum on-press efficiency and minimum material waste.

Our suite of software allows you to use Impact across multiple sites, standardising settings and specifications and sharing work with a wider team.

Customers can be brought into the tooling process, making you a company that is transparent and easier to work with.

> Built around a powerful and fully customisable design database to help manage and locate anything you create or edit

> Advanced tools to import and clean a wide range of other CAD and non-CAD drawings, ready for production

> A fully customisable interface and user-programmable tools make this the ultimate packaging design productivity suite

> The ability to automatically embed rules and specifications from you and your customers

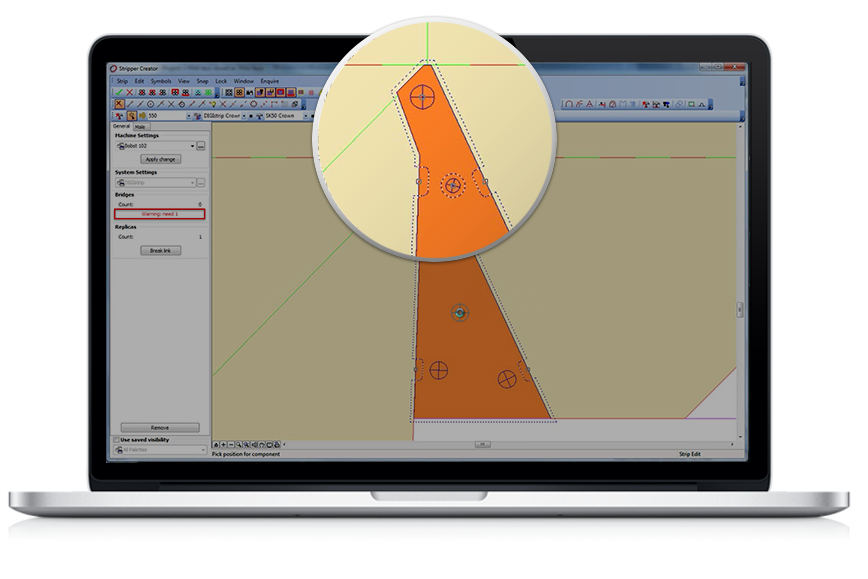

> Automatic tool registration, collision checking and alignment across a production job means quality control is built-in from the start

> From cartons to rubber parts, Impact’s complete nesting toolset offers time-saving and waste reduction that both you and your customers will benefit from

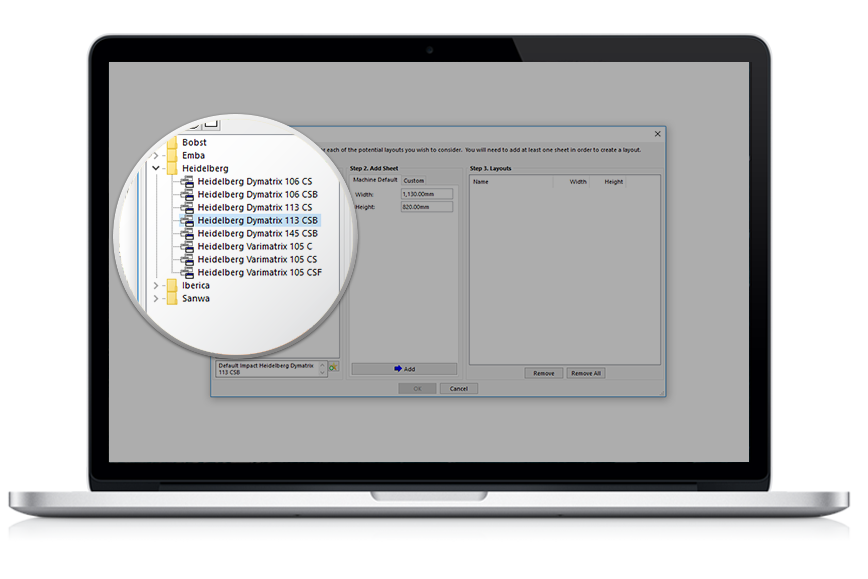

> Extensive library of pre-loaded machine parameters and ability for custom stock

> Error and clash detection tools for die-board and stripping units

> Designed by people who truly understand your business

> Compatibility with your machines and ways of working

> Elimination of errors

> Greater consistency

> Huge time savings for repetitive and complex work

> Scalable and bespoke – you choose the features you need and the software can evolve with your business

> Streamline manufacturing process by building libraries of customer-specific machines

> Configurable output machine drivers for all manufacturing areas

> Comprehensive file format support

IMPACT – ENTERPRISE BROCHURE – ENGLISH UK

IMPACT – ENTERPRISE BROCHURE – ENGLISH US

IMPACT – ENTERPRISE BROCHURE – GERMAN

IMPACT – ENTERPRISE BROCHURE – SPANISH

IMPACT – ENTERPRISE BROCHURE – FRENCH

IMPACT – ENTERPRISE BROCHURE – ITALIAN

IMPACT – ENTERPRISE BROCHURE – RUSSIAN

IMPACT – ENTERPRISE BROCHURE – CHINESE

What’s New in Impact 2019 – UK

What’s New in Impact 2019 – US

Impact user